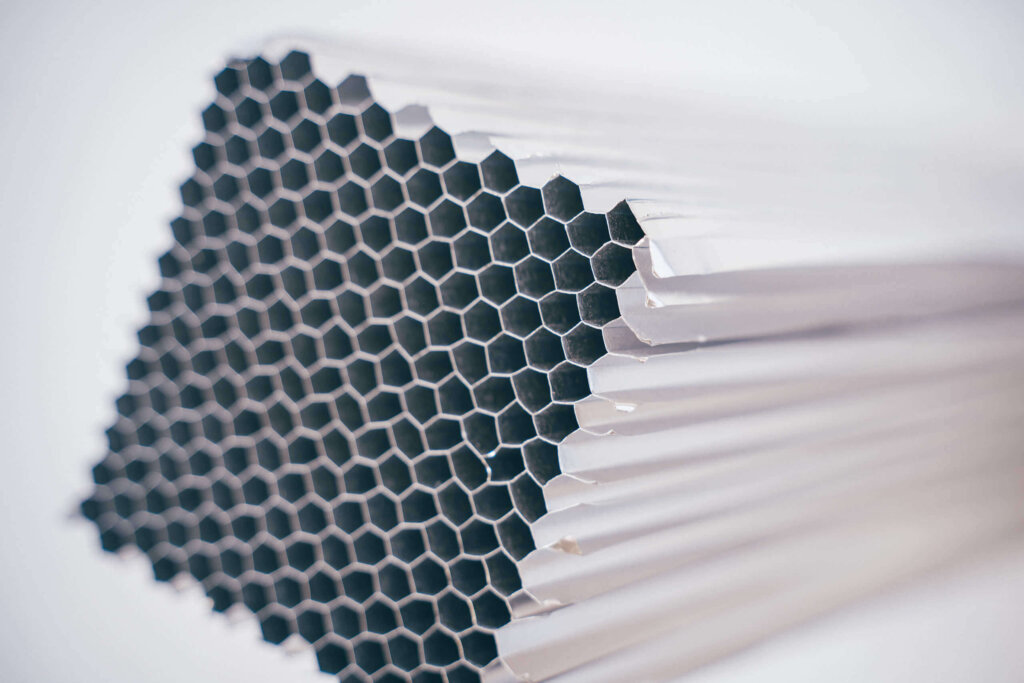

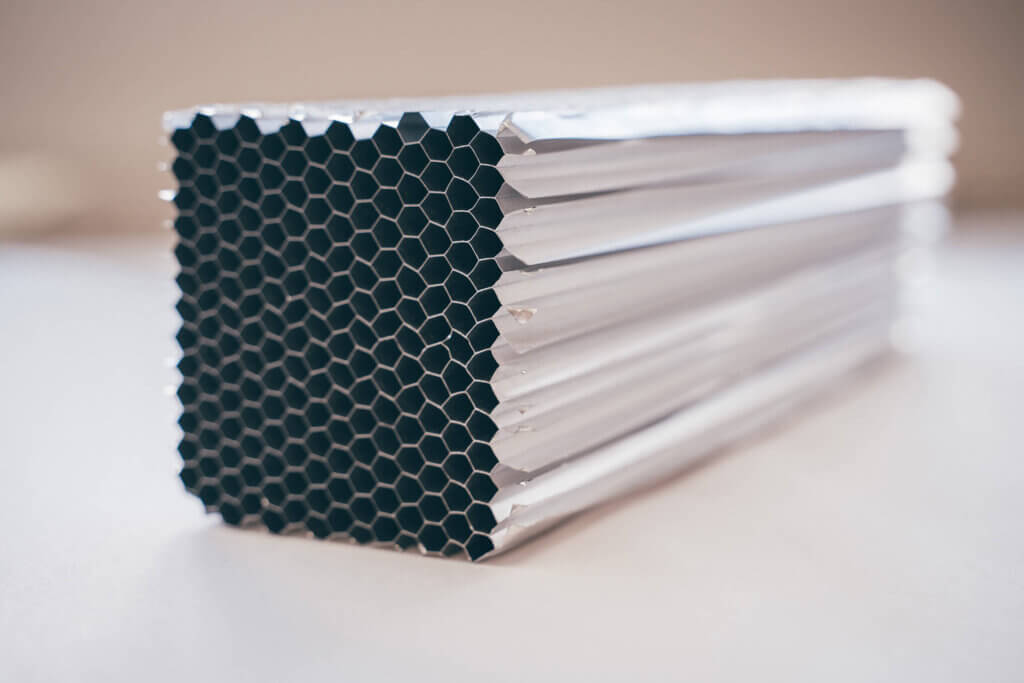

Aluminium Honeycomb Energy Absorbers

Corex Honeycomb is a leading aluminium honeycomb manufacturer with over 25 years of experience in the field of energy absorption. Thanks to our specialist knowledge, we can engineer and manufacture standard and custom energy absorbers for a wide variety of applications by manufacturing different cell sizes, core densities and crush strengths to produce absorbers of all shapes and sizes. Aluminium honeycomb is the perfect material for energy absorption applications due to its high strength-to-weight ratio. It also has excellent moisture and corrosion resistance.

Another advantage of using aluminium honeycomb for energy absorption is its ability to absorb forces over a large area. When the absorber is impacted, the cells are concertinaed (folded into one another). The energy required to do this is equal to the energy which is absorbed. This is an efficient method of preventing damage.

Corex Honeycomb Energy Absorbers can be supplied with an amount of pre-crush. This is where the first few millimetres of the absorber have already been crushed (concertinaed) and in so doing attenuating the initial force peak. The initial force peak is high but for a short duration, after which the force required to displace the honeycomb quickly reduces and stays at a constant level throughout the event. Energy Absorbers can be developed for bespoke project specifications, or for serial production for a wide range of applications including:

Motorsport

These products can help absorb the energy of an impact that occurs during a race and protect the vehicle and in doing so protect the occupants. They have also been successfully used to protect the fuel tank from impact.

Commercial

We can supply customer specific absorbers that provide impact protection for columns, racks and corners in warehouses and material handling facilities as well as many other applications.

Nuclear

When nuclear material is handled, Corex Honeycomb energy absorbers can be used as an insurance against unplanned incidents. It also has minimal impact on the shipping weight.

Rail

Typical applications in the rail industry include energy absorbing boxes for driver compartments and anti-climbers.

Shipping Protection

Corex Honeycomb energy absorbers can protect fragile products with minimal impact on the shipping weight.

Specifications:

Corex Honeycomb Energy Absorbers can be cut to the required size and supplied calibrated to a specific crush strength. For each batch of core, a number of material samples undergo compression testing in order to establish its force level throughout the crush and until densification, whilst ignoring the typical initial force peak.

Various densities, honeycomb cell sizes and aluminium alloys are available. The table below shows typical examples of aluminium honeycomb types:

| Density (pcf) | Cell size (inch) | Alloy | Crush Strength Range (psi) |

|---|---|---|---|

| 1.0 | 3/8 | 5052 | 21-30 |

| 1.3 | ¾ | 3003 | 24-35 |

| 1.6 | 3/8 | 5052 | 42.5-50 |

| 1.8 | ½ | 3003 | 30-40 |

| 1.8 | ¾ | 3003 | 42.5-50 |

| 1.8 | ¾ | 5052 | 50-60 |

| 2.1 | ¾ | 5052 | 70-90 |

| 2.3 | ¼ | 5052 | 70-90 |

| 2.3 | 3/8 | 3003 | 80-100 |

| 2.6 | ¼ | 5052 | 90-110 |

| 3.1 | 3/16 | 5052 | 125-155 |

| 3.7 | 3/8 | 3003 | 120-150 |

| 4.5 | 1/8 | 5052 | 240-320 |

| 5.2 | ¼ | 3003 | 225-260 |

| 10.0 | 1/8 | 3003 | 600-700 |

To find out more, please contact our sales team.