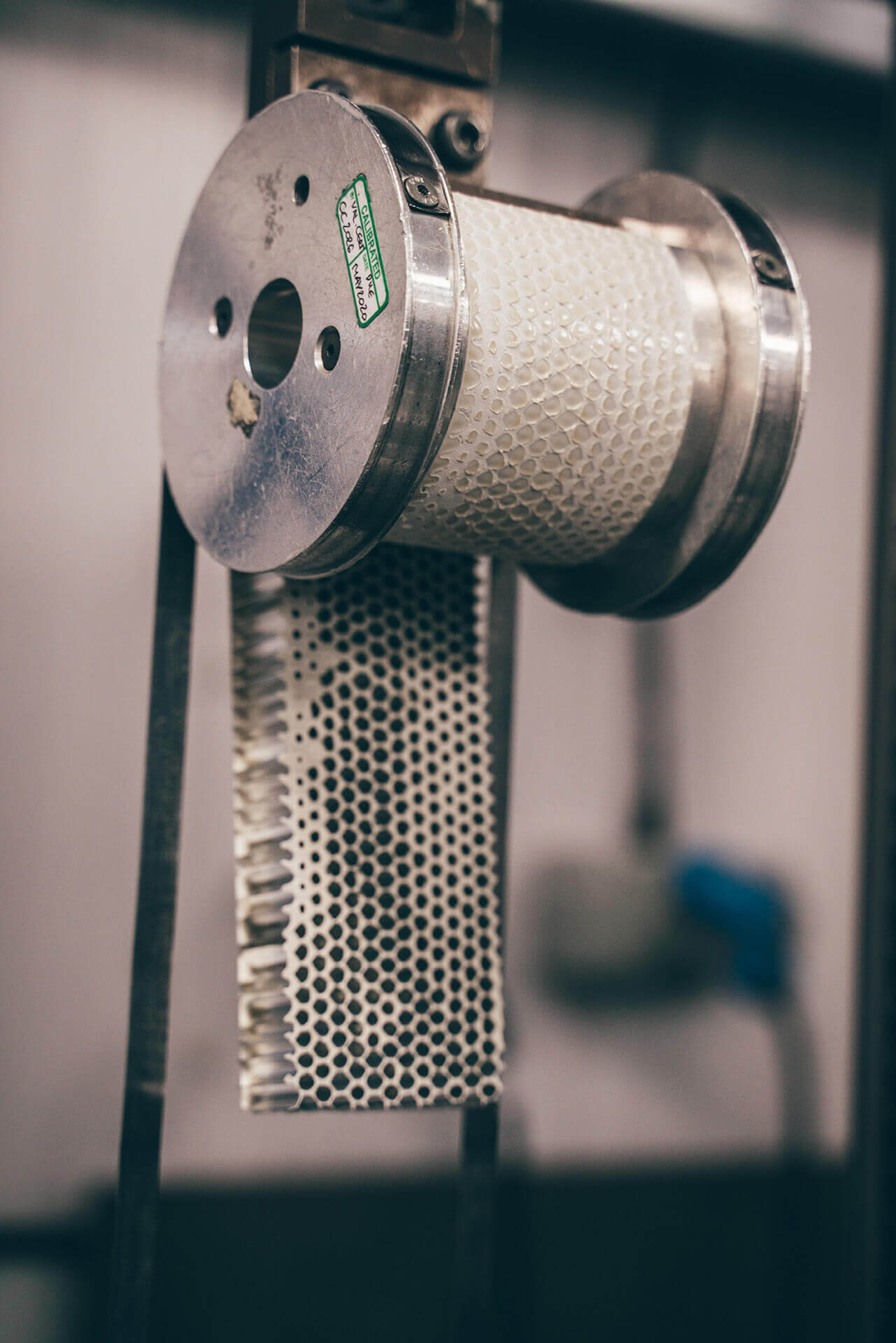

Test Laboratory for aluminium honeycomb structures

Corex Honeycomb’s manufacturing site includes Test Laboratory Facilities. Our stringent test procedures guarantee the highest level of accuracy for our customers, enabling us to perform tests on aluminium honeycomb structures. Tests available include:

| Test | Standard |

|---|---|

| Lap Shear | ASTM D1002-10 – A method for testing adhesion by pulling bonded layers apart along the plane of adhesion. |

| T-Peel | ASTM D1876-08 – A good accurate method of assessing the quality of a joint but is only applicable for flexible test pieces, for example aluminium foil. An example would be the force it takes to pull tape off a roll. |

| Climbing Drum | ASTM D1781-98 – A peel test but designed to understand the bond between a surface, or ‘skin’ and a sub-straight. In our case we usually test the bond between honeycomb aluminium and an aluminium skin. |

| Flatwise Tensile | ASTM C297/C296M-16 – Test specimens are cut from sandwich panels, and the faces of these specimens are bonded to aluminium blocks. The aluminium blocks are mounted in a universal test machine and pulled apart. This force, along with the area of the specimen is used to establish the bond strength. |

We use a Universal Test Machine (Inston or LLoyds machine) for each of the above tests. The samples are pulled apart at a pre-determined rate (mm per min), the force required to do this is continuously measured and recorded. This information is used to assess the strength of the bond.

Please get in touch to discuss your requirements and to find out more about the testing services we can offer.

Find more information here: Test Lab Datasheet