Laser Bed Cutting

A laser cutter is a prototyping and manufacturing tool used primarily by engineers, designers, and artists to cut and etch into flat material. Once a design is sent to a laser cutter, the machine uses a laser beam to slice into or etch into the material on the cutting bed.

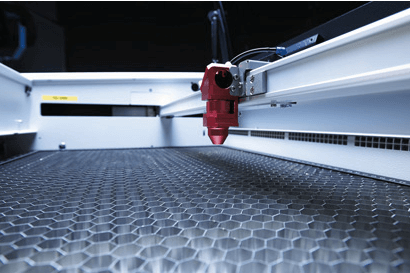

Aluminium honeycomb beds

During the cutting process, the material requires support from underneath. If a designer’s artwork is very dense or a less rigid material is being cut (for example paper or fabric), a honeycomb bed is required to keep the material flat and the structure allows the heat and waste material, caused by the process to escape. The lightweight high-strength characteristics of aluminium make it ideal for this application.

Due to the nature of repeat cutting, residue from the materials will build up over time on the aluminium honeycomb bed and the heat from the laser can cause these residues to transfer back onto the material being cut. For this reason, honeycomb beds with different cell sizes are used for different classes of material: plastic, wood, paper and card.

Aluminium Honeycomb beds are designed to be sacrificial and should be replaced on a regular basis to minimise contamination from material to material, this is a far more cost-effective solution than having to replace your laser machine bed.

The Process

Laser cutting can eliminate the need for machining on many engineering jobs, enabling savings to be made on the manufacturing costs. It has several advantages over plasma cutting as this process is more precise and uses less energy when cutting steel and aluminium sheets.

Laser cutters are used in machine shops on an industrial scale to cut large pieces of material, in hardware companies to create low cost, quick prototypes, and by artists as a fabrication tool to bring their digital designs to life.

When cutting stainless steel or aluminium, the laser beam simply melts the material, and high-pressure nitrogen is used to blow the molten metal out of the kerf (a cut made by the beam). On a CNC laser cutter, the laser cutting head is moved over the metal plate in the shape of the desired part, thus cutting the part out of the plate.

If you would like to purchase aluminium honeycomb for use as a sacrificial laser bed, please visit our online shop or contact us.