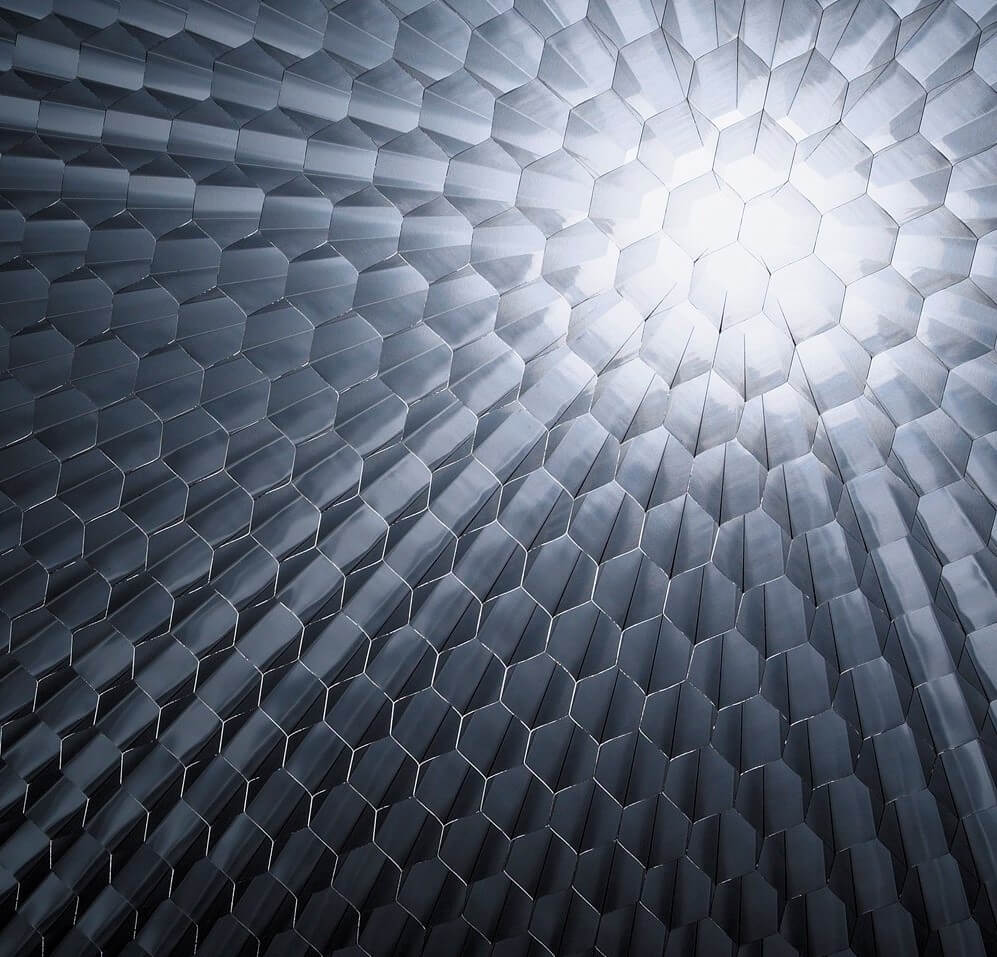

Aluminium honeycomb core material

Corex Honeycomb manufactures high quality aluminium honeycomb core material which is used in a wide variety of applications worldwide. Aluminium honeycomb is highly desirable due to its incredibly high strength-to-weight ratio and is applicable wherever lightness and strength are required. Corex Honeycomb supplies high quality aluminium honeycomb to global markets including the Aerospace, Marine, Rail and Automotive industries.

Why Aluminium? It has several benefits including:

- It is light-weight – 1/3 the weight of steel

- It is strong, corrosion-resistant and a good conductor of heat and electricity

- 100% recyclable, without any loss of its natural qualities

- It is easy to shape, form and fabricate

- Aluminium does not burn – it melts at 650 degrees centigrade

- When alloyed with another metal like Silicon or Magnesium, it can be stronger than Steel

Aluminium Honeycomb

The Corex range can be supplied in a variety of conditions, tailored to the individual needs of the customer:

- Expanded or unexpanded

- Full blocks or cut slices

- Perforated or unperforated

- Corrosion treated or untreated

- Aluminium Alloy Grade 3003 or 5052

Corex standard honeycomb can be expanded to the following sizes:

- W 2500mm x L 1250mm

- W 3000mm x L 1500mm

Other block sizes are available on request. Depending on cell size, up to 18000mm can be achieved in the W direction.

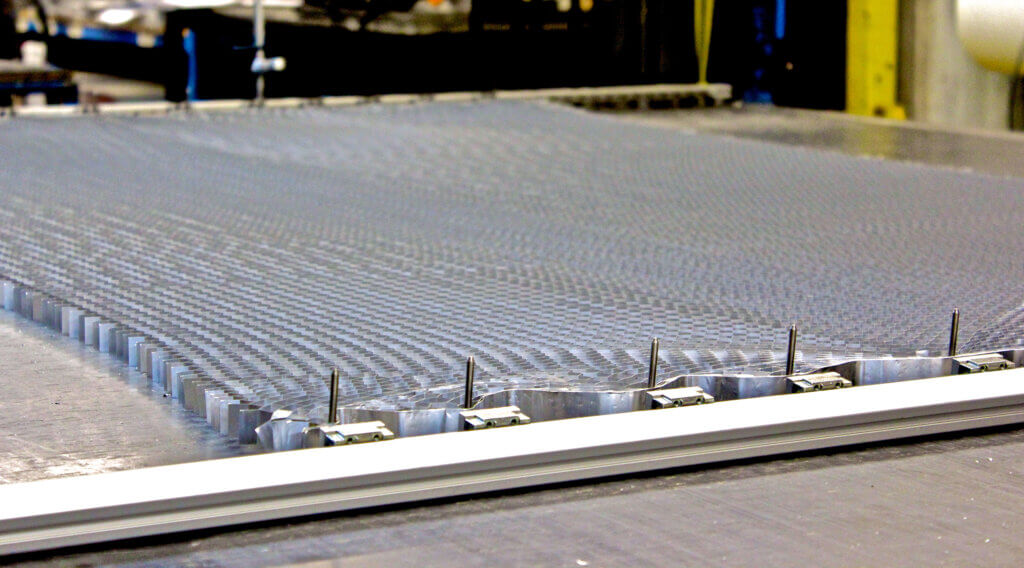

Aluminium honeycomb can potentially be expanded “by hand” when slices are thin and/or with a large cell (1” and ¾”). However, for thicker honeycomb slices, a small cell size and/or high density, specialist automated expansion equipment will be needed. Corex can supply aluminium honeycomb in both expanded and unexpanded formats. Please contact us for further information, or read our blog for more details.

Corex Honeycomb is manufactured with Aluminium Alloy Grade 3003 or 5052; both standard products are normally supplied in an unprocessed condition.

Honeycomb blocks can be cut to thicknesses to suit individual customer requirements. Using the latest cutting technology, Corex Honeycomb is able to supply slices up to a tolerance of ±0.125mm with a minimum slice thickness of 3mm.

Engineering support

Corex Honeycomb is part of a group with more than 30 years’ experience in composite manufacturing, engineering and design.

Applications

Aluminium honeycomb can be used in a virtually unlimited number of applications. Some of the most widespread applications are as follows:

Rail

- Doors

- Floors

- Sanitary Modules

- Energy Absorbers

- Furniture

- Walls

- Dividing Panels

Marine

- Interior Panels and Partitions

- Furniture

- Ceiling and Flooring Panels

- Hulls and Bulkheads

- Doors

Construction

- Building Facades

- Ceiling and Flooring Panels

- Clean Rooms

- Furniture

Industrial

- Exterior architectural curtain wall panels

- Flow Straightening ( Air and Liquid)

- Heating and Ventilation

- Electromagnetic shielding

- Sacrificial Beds (Laser and Waterjet)

Automotive

- Motorsports

- Commercial and Military Vehicles

- Impact Energy Absorbers

Wind Turbines

- Rotor Blades

- Turbine Cladding

- Mould Construction

For detailed information on Corex Honeycomb’s aluminium honeycomb please contact our sales team.