Superflex – Flexible Aluminium Honeycomb

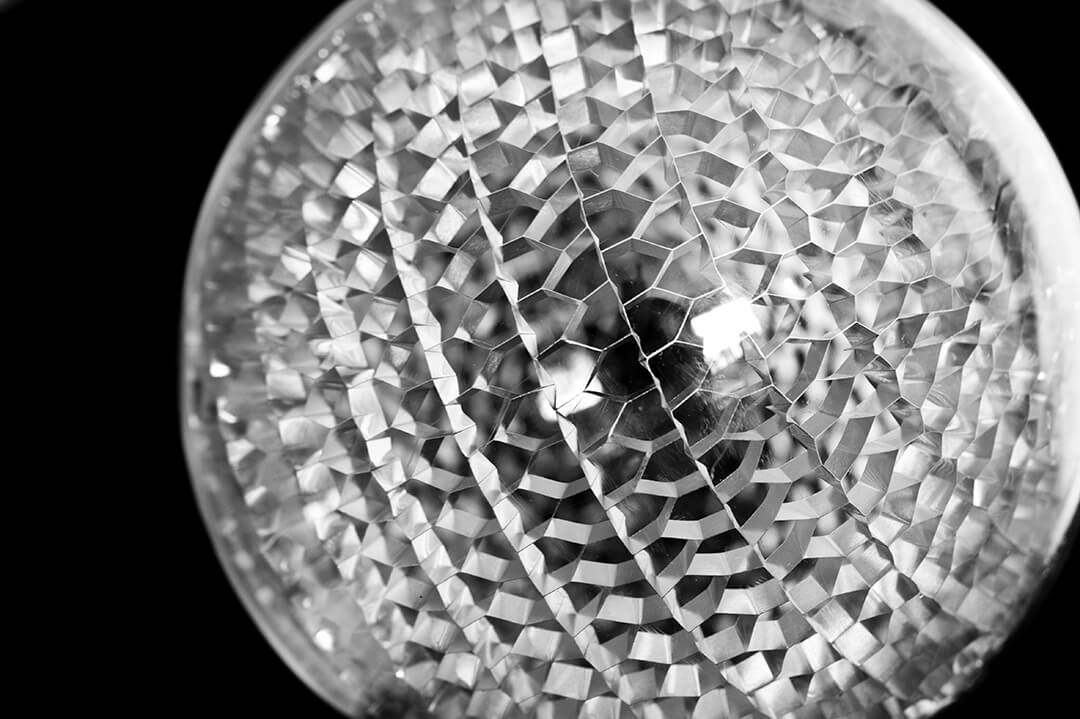

The Corex team have been working in collaboration with our Project Engineer department to develop a flexible aluminium honeycomb. By adjusting elements of our production process, the cell geometry has been adapted so the aluminium honeycomb can bend and flex. The resulting benefit of this cell configuration is that the flexible honeycomb can be used for curved panels, spherical, cylindrical and organic shapes. The product can be produced with 3003 and 5052 alloy grades and has the same properties as our standard hexagonal cell shaped aluminium honeycomb. Before this flexible honeycomb was available it was difficult to work with certain shapes and forms, with a complex process of assembly required with several individual pieces of honeycomb cut into different shapes. This new product has excellent formability and is easier to use round shaped surfaces.

As a sandwich panel, the flexible honeycomb can be used for a wide range of applications, including train interiors, architectural structures, boat hulls, car and caravan body panels. Another target market for this product is sports helmet manufacturers, as its properties can also provide protection to the wearer. As with our standard aluminium honeycomb, the product adds strength without increasing the weight significantly.

Contact our sales team for further details.

Motorsports can benefit from flexible aluminium honeycomb

Boat hulls can be fitted with flexible aluminium honeycomb

Flexible aluminium honeycomb