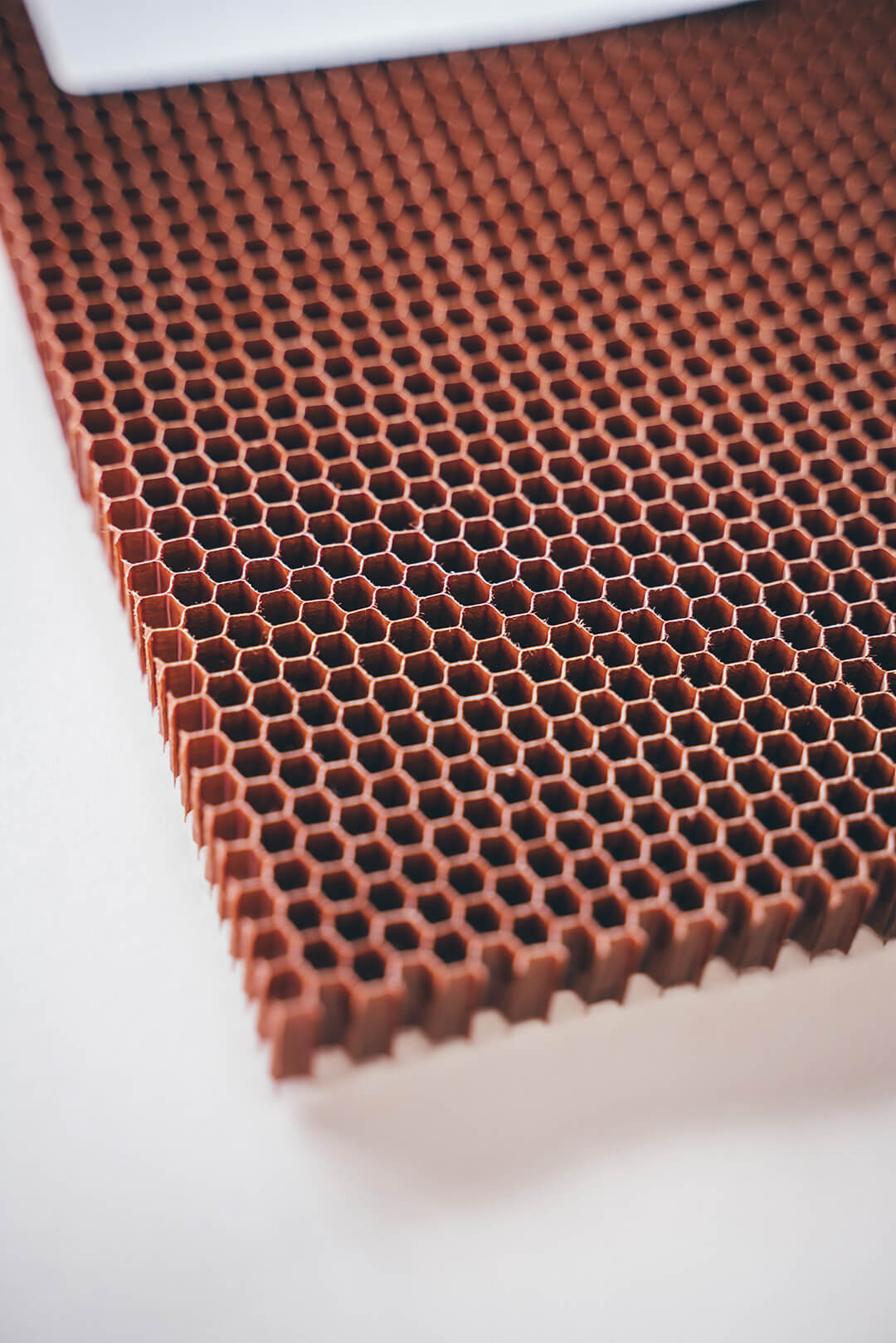

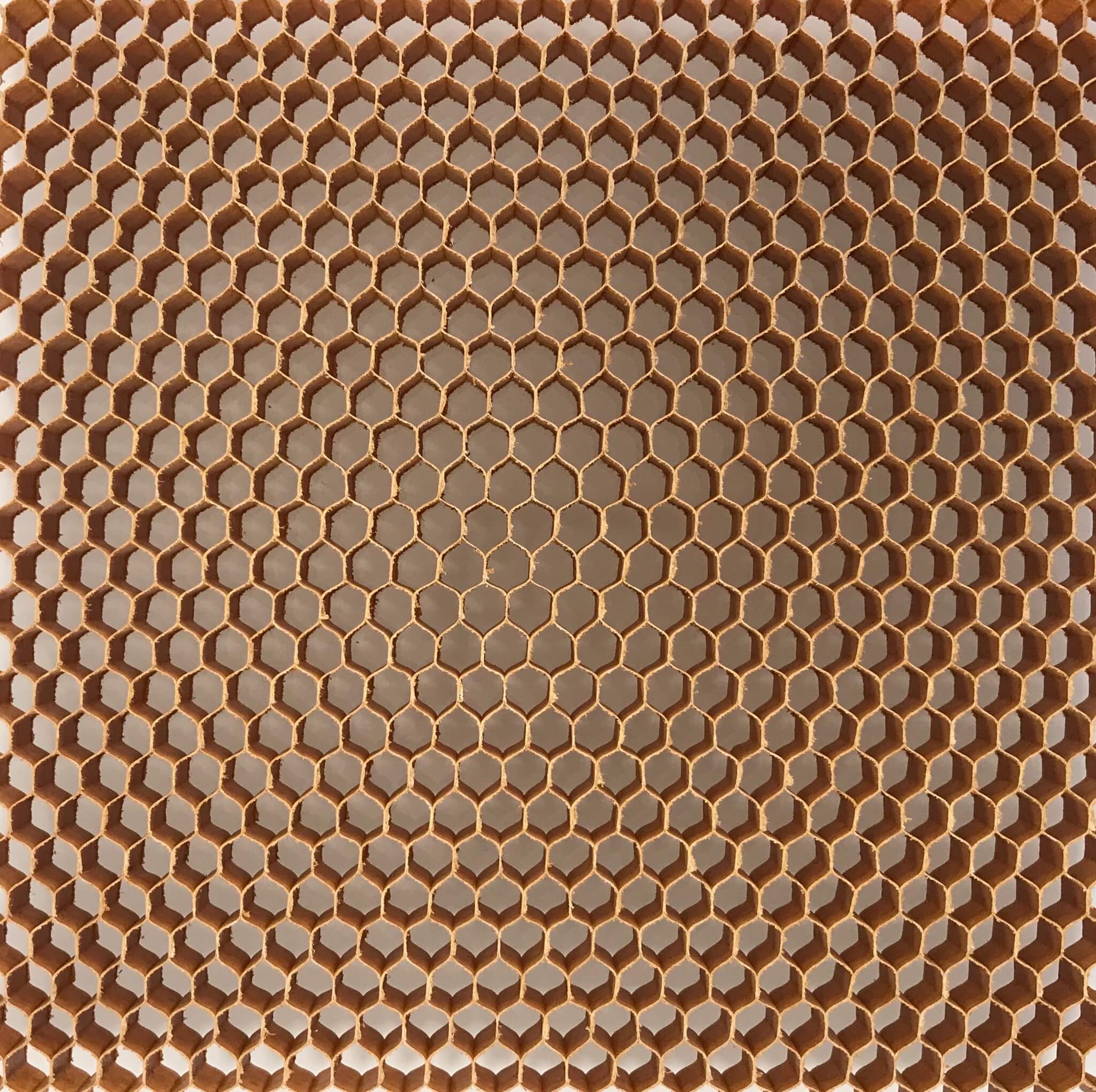

Nomex and Kevlar aramid paper honeycomb range

We can now provide our customers with a range of Nomex® and Kevlar® aramid paper honeycomb core, working with Schutz Cormaster. Nomex® and Kevlar® are aromatic polyamides or aramids developed by DuPont™. Nomex® is a flame-resistant material known for its exceptional durability and rigidity; Kevlar® is a heat-resistant fibre with very high tensile strength, known for its ability to withstand high impact.

Minimum order value £250

Short lead times for stock items

The range comprises of Aerospace and Industrial grade products:

Aerospace Grades

N636: Made with Kevlar® N636 paper for structural applications where low weight and maximum performance are required.

Benefits: Extremely high shear modulus, 1.5 to 3 times higher than Nomex® honeycomb at the same density. Excellent compressive strength, 20% higher than Nomex® honeycombs in terms of density.

C1: Made with Nomex® T412 paper for main aerospace structural and cabin applications.

Benefits: Self-extinguishing and low fume toxicity

Industrial/ Commercial Grade

C2: Made with Nomex® T722 paper and is ideally suited to structural sandwich applications in the automotive, marine, rail, transport and sports industries.

Benefits: Offers excellent value for money with superior mechanical properties and a high strength to weight ratio.

This new range of non-metallic honeycomb fully complies with a rigorous quality management system that meets EN ISO 9001 standards which apply to the aviation and aerospace industries.

Additional services

In addition, we are also able to offer the following new services:

Machined Nomex® and Kevlar®:5-axis machining of three-dimensional pieces to customers own designs, up to the maximum dimensions of 2,200mm x 6,500mm x 1,140mm. CNC-controlled machines ensure precise edges and holes, even on curved surfaces.

Formed Nomex® and Kevlar®: Using in-house produced tools and special furnaces for cold and hot forming; we can produce moulded parts measuring up to 4,000mm x 2,500mm x 2,500mm.

Bonded Nomex® and Kevlar®: To be able to specifically adjust the properties of the honeycomb structure in different areas of a component, we can combine different types of honeycomb. For example, zones with over-expanded honeycomb allow flexible curvatures in otherwise rigid structures

Stabilised Nomex® and Kevlar®: To obtain special characteristics, the honeycomb can be filled with a variety of different materials in a fully automatic process.

If you have a project requiring Nomex® or Kevlar® paper honeycomb or require further information about the range, please contact our sales team.

For further examples of applications please see the Cormaster website.

The addition of Nomex® or Kevlar® paper honeycomb compliment the range of composite materials within the Corex Honeycomb range which includes aluminium honeycomb and Tubus Waben polypropylene honeycomb.