Polypropylene honeycomb

Project with The Royal Academy of Art

The polypropylene honeycomb (PP), which Corex Honeycomb distributes in the UK, is manufactured in Europe by TUBUS WABEN GmbH &Co. KG. It is an ideal component for any lightweight assembly, as it is extremely light but very strong. It provides high stability at a low weight and is resistant to both heat and corrosion.

The basic raw material for producing the honeycomb is polypropylene, a thermoplastic, recyclable material from the polyolefin group. It is ideally suited to being a semi-finished product that is primarily used to produce sandwich composite components.

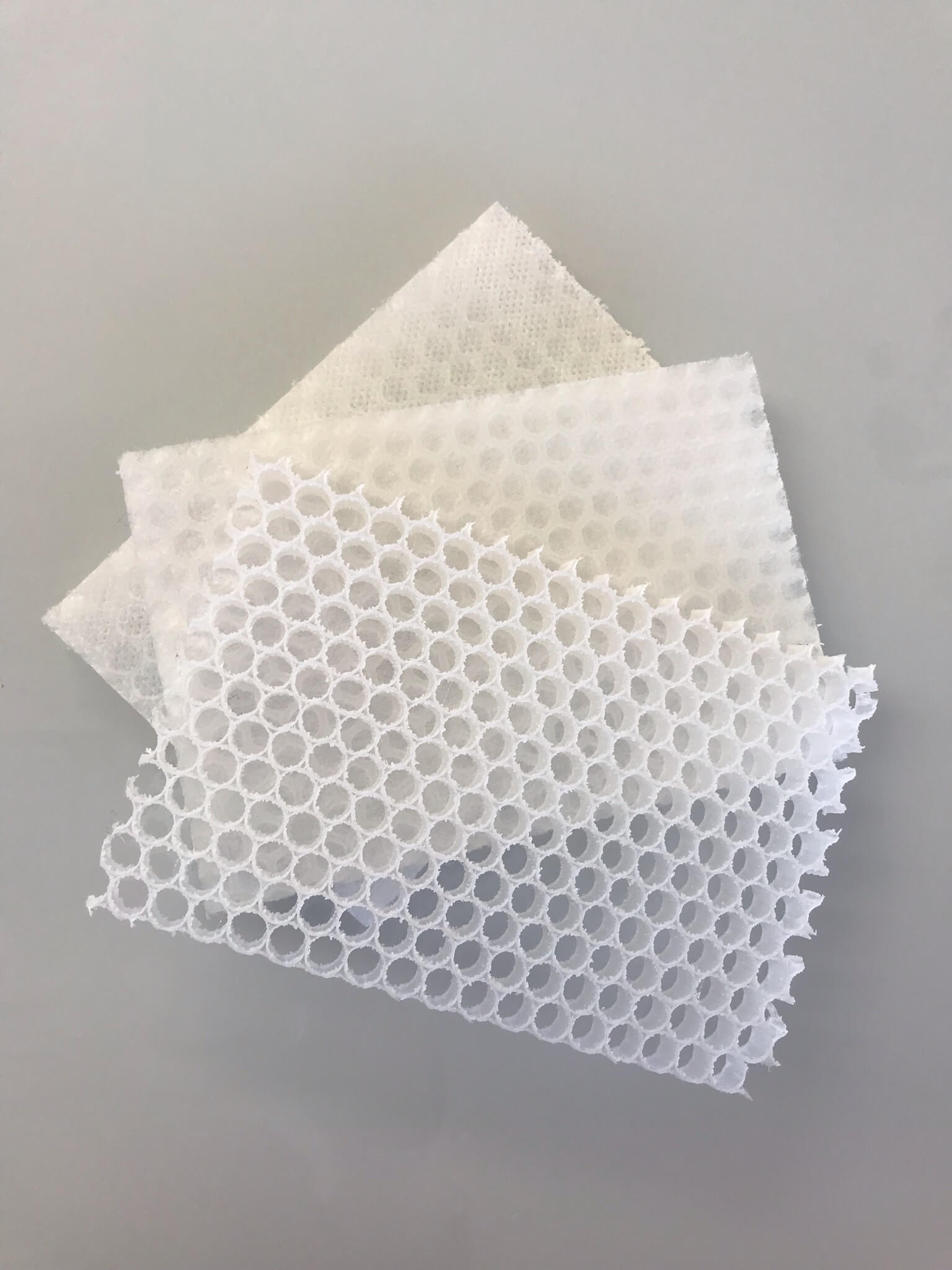

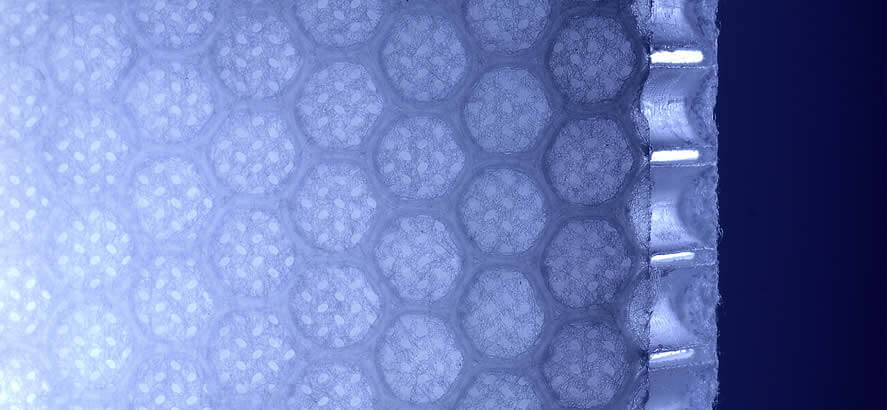

Traditional honeycomb is assembled from hexagonal shapes but Tubus Waben are the only European manufacturer of PP honeycomb with the circular cell, manufacturing in excess of 500,000m2 annually. The unique circular cylinder formation can accept forces from various directions and still maintain shape. These isotropic mechanical characteristics of the individual honeycombs ensure high stability for the whole honeycomb plate and therefore also the final product. Through the use of polypropylene as the initial material, they are resistant to corrosion and their handling is extremely flexible. Polypropylene honeycomb is available in four designs:

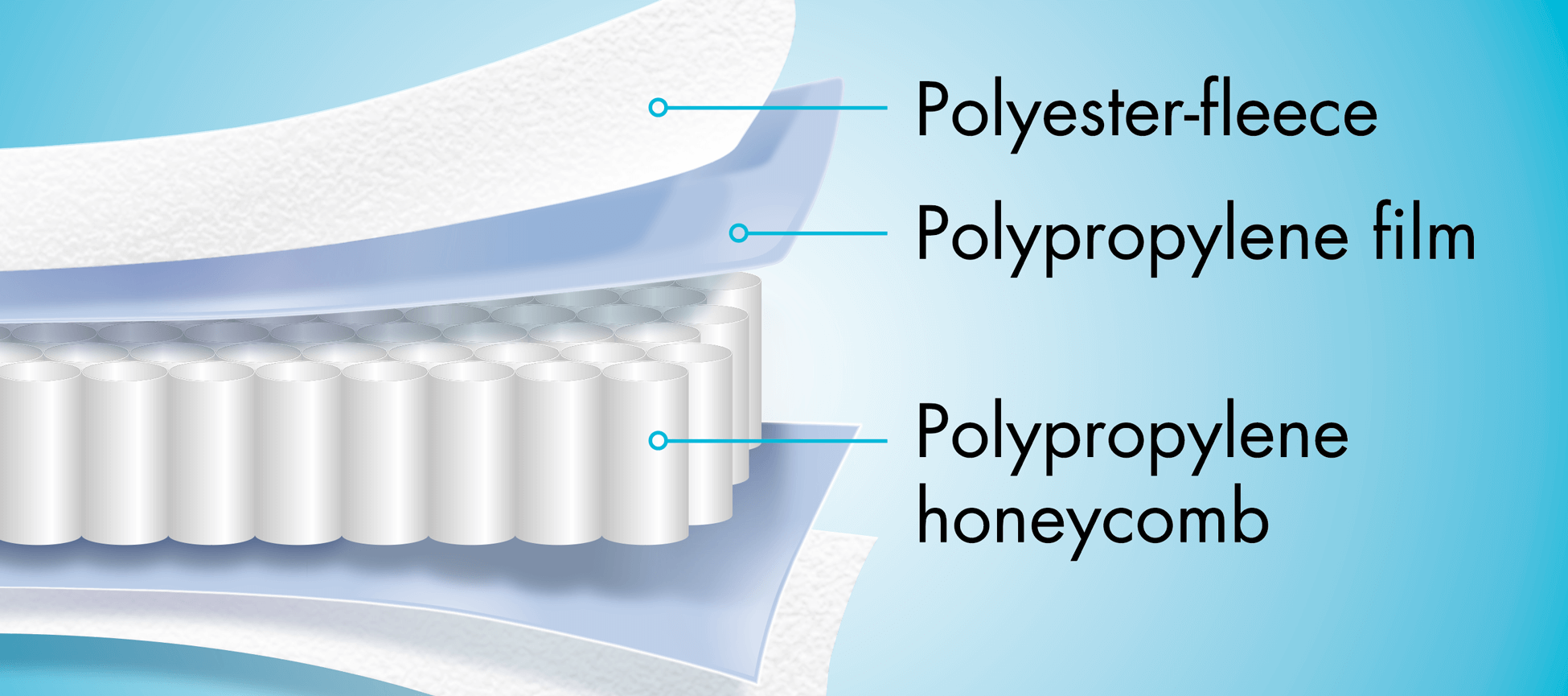

- Without lamination (bare),

- Laminated with polyester fleece

- Laminated with polypropylene film combined with polyester fleece

- Suitable for Vacuum Infusion

A film or fleece is attached and thermally connected with the polypropylene honeycomb as a lamination layer. The polyester fleece is used as an adhesive for further processing. When using liquid resins the polypropylene film guarantees that the honeycomb material is free of resin and does not fill the hollow spaces in the honeycomb.

As a result of its thermoplastic properties, plastic honeycomb can be shaped thermally and can be cut to the desired shape using conventional tools. The polypropylene honeycombs are ideally suited for use in composites. With suitable processes and resources, virtually all materials can be attached as a cover layer on Corex polypropylene honeycombs. Fibre composites (Glass Reinforced Plastic, Glass Mat Reinforced Thermoplastics), metal sheets, wooden plates, High Pressure Laminate cover layers or minerals are frequently used.

The advantages of polypropylene honeycomb:

- Extremely light, low weight: 60 bis 120 kg/m3

- Extremely strong: high tensile strength, bending and pressure resistance

- Extremely versatile: virtually unlimited application possibilities

- Corrosion and moisture resistance

- Reduces noise and vibrations

- Highest dimensional stability due to precise cutting

- Can be thermally moulded

- Can be recycled

Polypropylene honeycomb is ideally suited to Commercial vehicle construction, Boat and ship building, Rail vehicle construction, Automotive, Transport/ logistics, Construction and Wind power systems. It ensures a reduction in mass and at the same time offer particularly high pressure, impact and bending stability, low water absorption and freedom from corrosion. In line with our extensive environmental credentials, polypropylene is an environmentally friendly plastic as it is 100% recyclable.

Polypropylene honeycomb datasheets: Please download the data sheets for further technical information.

To find out more please contact our sales team.