Aluminium Honeycomb for Air Conditioning, Wind Tunnels, Diffusing & Shielding, Sacrificial beds

Aluminium honeycomb is suitable for use in a range of specialised applications including air conditioning, wind tunnels, diffusing, electromagnetic shielding, flow straightening and sacrificial beds. Corex Honeycomb offers a material that does not significantly alter the weight of applied product, whilst efficiently directing air flow, liquid and light. The open cell structure allows maximum flow with minimal resistance.

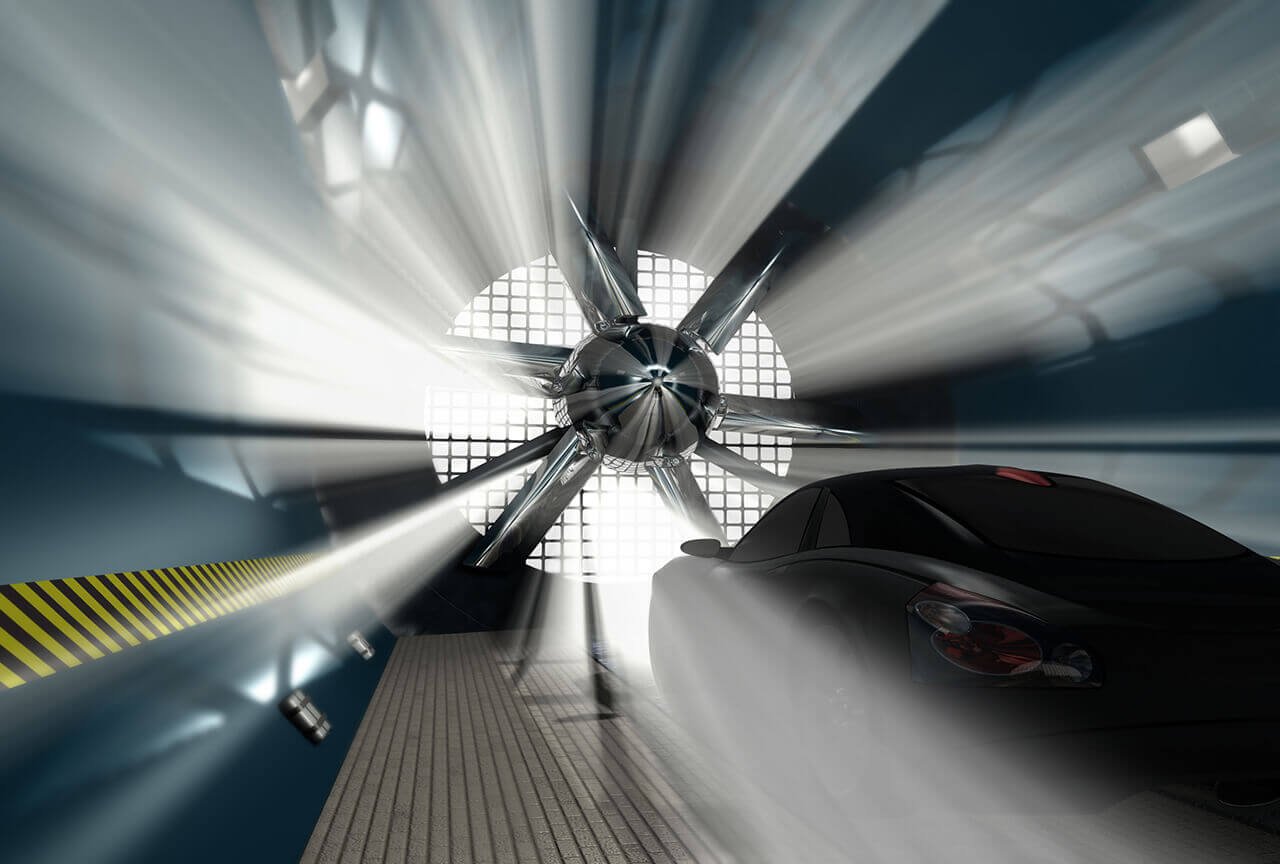

Corex aluminium honeycomb is used as a flow straightener in ventilation panels and for wind tunnels. The ventilation panels can be used in electronic enclosures where good air flow is required. Wind tunnels are used in aerodynamic research to study the effects of air moving past objects. The object being tested is placed on a mount inside a tubular passage. Air is made to move past the object using a powerful fan system. The test object is instrumented with sensors to measure aerodynamic forces, pressure distribution and other aerodynamic-related characteristics.

A light diffuser , when placed in the path of a source of light will soften the illumination effect, with the honeycomb structure directing and filtering the light. This effect is used in photography where the light from one concentrated source, can be spread out, bounce from reflective ceilings and walls, thus eradicating harsh light and hard shadows.

Electromagnetic shielding is the practice of surrounding electronics and cables with conductive or magnetic materials to guard against incoming or outgoing emissions of electromagnetic frequencies.

When used as a bed for the water jet and laser cutting, the material lies flat during the cutting process, supported by the aluminium honeycomb. The honeycomb structure allows the heat and waste material, caused by the process, to escape. The lightweight, high-strength characteristics of aluminium make it ideal for this. As a result of the repeat cutting, residue will build up over time on the bed, this sacrificial characteristic requires the bed to be replaced regularly to prevent contamination, a more cost effective solution than replacing the whole machine.